Concepts with a future

The continuous growth of our company in the field of contract assembly and the increasing takeover of project management has led to the establishment of a separate department for project management and plant engineering since the mid-1990s. With decades of experience, we assess new technologies according to their practical suitability for future-oriented and successful productions.

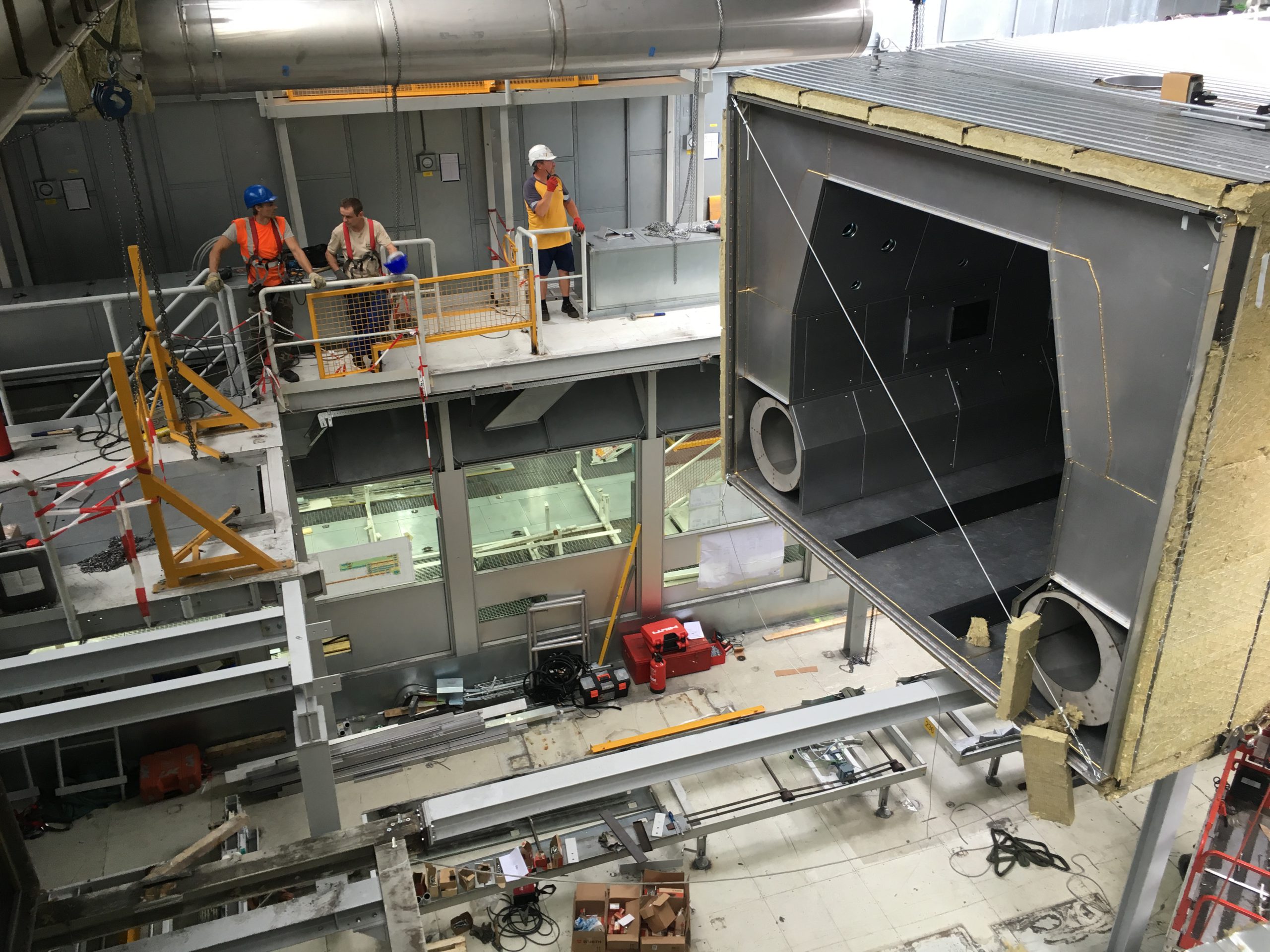

Goals and methods – we develop the system concept together with our customers. This enables fundamental process engineering decisions, process simulation and installation planning to estimate the space required. The initial cost estimate is derived from data from existing systems. Planning – systematic evaluation and detailed realisation of the plant concept as a concrete plant model. This includes the layout, technology of the individual units, automation, control technology, measuring principles, energy requirements and risk classifications. The finished model serves as the basis for specifying the process engineering, machine and apparatus technology and process automation, as well as for scheduling the construction and assembly processes. Following tenders and enquiries, the planning phase ends with the awarding of individual contracts. Realisation – the assembly documents and work orders make it possible to monitor the current status of the project progress, both during assembly and in the course of test runs and commissioning. It ends with process validation and optimisation.

Our installation services in detail

We are at your side with our experience

How can we help?

We are happy to answer any questions and provide comprehensive advice on our services.